When Seconds Matter

When operating CNC Swiss machines, every second counts. Producing small parts quickly and minimizing machine downtime is essential for profitability.

For example, one of our local CNC Swiss shops recently faced a challenging project involving a large order in Kovar, a notoriously difficult material. The job required drilling very small holes—1.09mm (0.043”) in diameter—adding to the complexity. Partnering with Nachi, we demonstrated the S&D Difference on their shop floor.

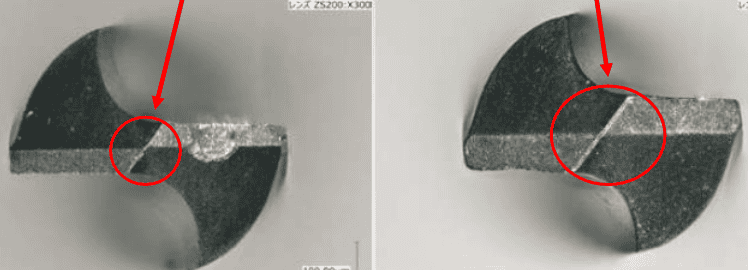

Working closely with our local representative, Cary Schlegel, we introduced Nachi’s Micro REVO drill. The original drill used in the operation broke after about 200 parts, causing significant machine downtime. It also operated at a relatively slow feed rate of 1.76 IPM.

The Micro REVO drill, with its thicker core and improved chip evacuation, delivered a game-changing performance. We increased the feed rate to 4.24 IPM—more than double the original—and reduced cycle time by an impressive 20 seconds per operation.

As a bonus, the Micro REVO drill far outperformed the previous tool, completing 1,000 parts flawlessly before we left. It also provided better hole quality, improving the performance and tool life of the subsequent micro boring bar operation.

Thanks to the reduced cycle time and increased machine uptime, our customer estimated a cost savings of $9,888 on their 14,000-piece run.

Nachi Micro REVO Drill (1,000 parts )

Competitor Drill (200 parts)

Our sales team and manufacturing partners are ready to deliver these kinds of performance enhancements for your most demanding projects. Contact us today to experience the S&D Difference firsthand!