Aluminum Plate Drilling

Recently, for a longtime customer, we had the opportunity to not only to supply the correct tooling but also to assist in process improvement for aluminum plate drilling. Our customers know they can rely on us to provide solutions to their productivity improvement process.

Case in Point

We were presented with a challenge to improve the process on a large aluminum plate job, with each plate having over 1000 holes that were over 1.5” thick. In total, the job included six plates.

Scenario

With the original program and tooling, each plate was estimated to take 60 hours.Our salesperson, Brandon Sakata, was called in to “take a look” at the job. After spending time with the shop personnel and programming departments.

Solution

S&D recommended new tooling and a change in the drilling process. With just the modest tooling expense, the drill time for every hole was reduced from the originally programmed time of 4 minutes per hole, to 30 seconds per hole. The results were dramatic.

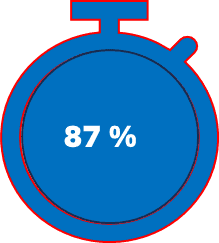

From an estimated run time of 60 hours per plate, we were able to reduce that to 8 hours complete, saving an estimated 52 hours per plate.

Net savings to our customer:

52 hours at an average shop rate of $150 per hour.

$7,800.00 saved per plate.

$7,800.00 X 6 plates.

$46,800.00 saved in total.

We look forward to these opportunities to work with our business partners and improve processes and profits wherever possible. If your team is looking to improve on a similar process, learn more about our hole making, boring and threading solutions and give us a call at (714) 956-8665.