Solutions

Innovative Solutions for Aluminum Extrusions

Innovative Solutions for Aluminum Extrusions In the competitive aluminum extrusion manufacturing industry, S&D’s customer faced challenges with poor tool life and frequent breakage, leading to high tooling costs. To address this, S&D introduced a solution from LMT ONSRUD, a leader in cutting-edge solutions for aluminum extrusions. The success stories of LMT ONSRUD highlight the effectiveness…

Read MoreThe Power of Inventory Management

Significant Growth led to overspending and stock outs A cutting-Edge Space Company experienced significant growth in recent years. However, this growth also posed some challenges for the company’s tooling management system. Challenge Tooling items, such as cutting tools, inserts, and holders, are essential for the Space company’s machine shop to produce quality parts that meet…

Read MoreThe 60HRC Drill Challenge

Recently, a client took on a job as a favor to assist one of their regular customers. However, they discovered that the D2 Steel material, originally specified at 40 HRC hardness, was received at 60 HRC hardness due to an error in the customer’s order. With the longer lead time for the material, the client…

Read MoreFrom Scrap to Cash

In the manufacturing industry, the costs associated with scrap are widely recognized. This is especially true when dealing with investment casting parts that have undergone extensive machining. A single mishap during this process can result in significant waste of both time and money. Recently, one of our clients encountered a similar scenario. During the final…

Read MoreMore Than Just Tooling

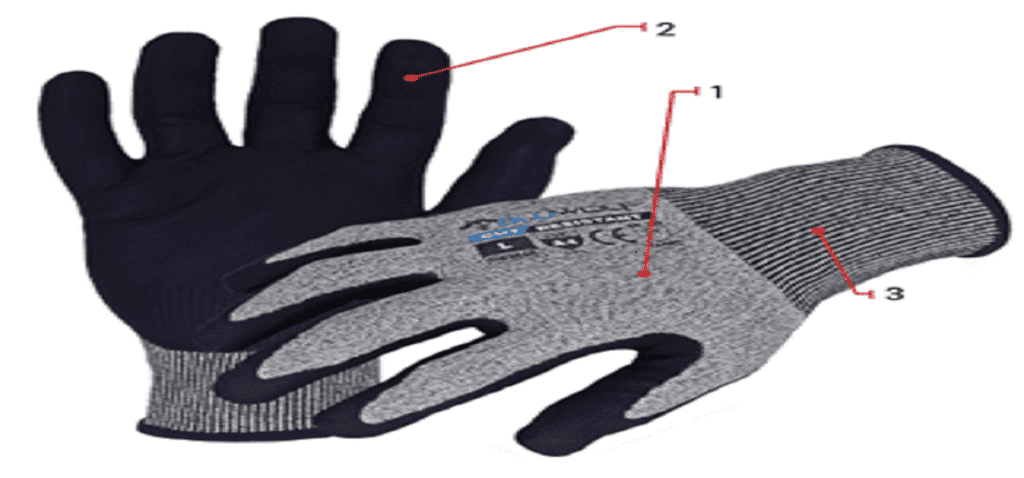

While S&D primarily specializes in cutting tools and the application of those tools. We also work to meet all our customers to meet their PPE (personal protective equipment) needs. A large machine shop, with about 125 employees, utilizes one of the VMI systems we offer to manage the inventory and PPE needs. Our sales associate…

Read MoreTriumph in a Titanium Trial

At a prominent aerospace shop, they are roughing Titanium every day. The customer was pleased with how the job was running. They were making the quoted time and had been doing the same jobs for months, using the same tools. “Good enough,” are not words our sales team accepts, so we challenged our customer…

Read MoreS&D Difference – Maximizing your Profitability

In the semiconductor industry, large runs and throughput are the keys to profitability. A local semiconductor company operates in just this way. They have been enjoying running the same parts for years and have been happy with the tooling. When an opportunity arose for S&D’s Darren Dives, to go over the job with the…

Read MorePlug And Play

There are just times when due to many different circumstances, CNC programs or tool paths cannot be changed. It could be either time constraints or lack of programming resources at a customer. The team at S&D in such scenarios is very adept & versatile at making the most of the available resources to improve…

Read MoreAluminum Plate Drilling

Recently, for a longtime customer, we had the opportunity to not only to supply the correct tooling but also to assist in process improvement for aluminum plate drilling. Our customers know they can rely on us to provide solutions to their productivity improvement process. Case in Point We were presented with a challenge to improve…

Read MoreThe S&D Difference

Our customers know they can rely on us to provide solutions to their productivity improvement process. Case in point S&D partnered with our customers and suppliers to reduce cycle time to meet production requirements without adding machines or additional personnel, but running other projects. Scenario Running on a CNC vertical mill, steel casting, requiring 52…

Read More