Triumph in a Titanium Trial

At a prominent aerospace shop, they are roughing Titanium every day. The customer was pleased with how the job was running. They were making the quoted time and had been doing the same jobs for months, using the same tools. “Good enough,” are not words our sales team accepts, so we challenged our customer to allow us to demonstrate what is possible.

Our customers start parameters using a 5-flute carbide end mill .750 diameter x 2.250 flute w/ .030 radius.

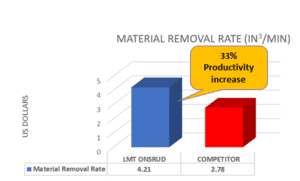

SFM = 325 – IPT = 0.0059 or 48.8 IPM with 5% Radial WOC (0.035”) and 1.5” Axial LOC.

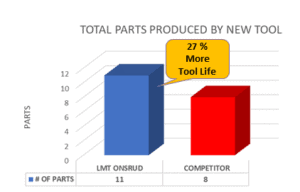

Result: A respectable material removal rate of 2.78 cubic inches and they were able to complete eight parts.

Chandan Shiroy, our VP of Operations, and round tool expert, introduced the LMT Onsrud TRX series end mill. The TRX series geometry and coating allowed us to increase the WOC to 7% (.053’) and move the Axial LOC to 1.625” while maintaining the same feeds & speeds.

Result: The higher WOC & Axial LOC resulted in a higher material removal rate of 4.21 cubic inches and increased the part output to eleven parts.

Figure 1 LMT Onsrud - TRX Series 5-Flute Endmills for Titanium Machining

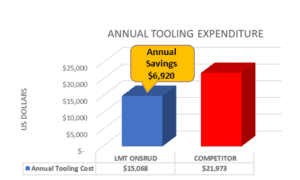

Customer Benefits & Savings:

1. Increased productivity by 33%

2. Increased Tool life by 27%

3. Customer realized an annual savings of $6,920

Do not settle, let our team of application specialists bring these results to your shop floor. Experience the S&D Difference for yourself.