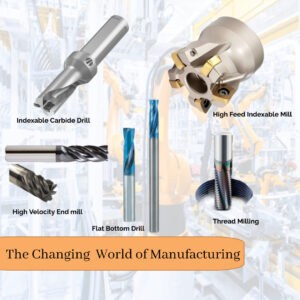

The Changing World of Manufacturing

Over my 48 years in the machining industry, I've witnessed incredible advancements that have redefined how we manufacture products, from everyday items to cutting-edge technologies. It's easy to overlook the impact of innovations that have become standard practice.

Here are a few key products introduced during my career that truly changed the game:

Indexable Carbide Drills: Faster Material Removal & Increased Efficiency

These drills, particularly with their early trigon inserts, revolutionized drilling. They offered over five times the penetration rate, significantly reducing cycle times and making them the fastest way to remove material. The later square insert design added the crucial ability to drill on complex surfaces and minimize breakout on cross holes.

High Feed Indexable Milling: Transforming Milling Productivity

This technology has become the dominant force in modern milling. By utilizing lighter cuts and extremely high feed rates, it dramatically increases metal removal rates, especially in challenging materials like titanium and Inconel. The predictable tool life also enhances unmanned manufacturing capabilities.

Thread milling: Eliminating Scrap & Ensuring Thread Quality

While established for some time, the intelligent application of thread milling has been a major factor in reducing scrap. As a final operation, threading is high-risk. Thread milling's multi-pass approach guarantees thread quality, and its smaller size minimizes potential damage upon breakage, often allowing for repair. Newer techniques even enable top-down threading for difficult materials.

Flat Bottom Solid Carbide Drills: Unlocking Versatility in Drilling

Often underestimated, these drills offer exceptional versatility. They can drill on round and angled surfaces (up to 45 degrees) and through cross holes without requiring a flat spot. This has streamlined processes, such as in the connector industry where one tool now replaces three. They also serve as effective flat-bottom counterbores.

High Velocity Milling: Maximizing Material Removal with Solid Carbide

This programming concept, while applied to existing tools, has brought the high-feed, light-cut advantages to solid carbide end mills. By using shallower, faster radial cuts with greater axial engagement, end mills with more flutes can be used without chip packing issues, resulting in higher feed rates and faster overall material removal.