Innovative Solutions for Aluminum Extrusions

Innovative Solutions for Aluminum Extrusions

In the competitive aluminum extrusion manufacturing industry, S&D's customer faced challenges with poor tool life and frequent breakage, leading to high tooling costs. To address this, S&D introduced a solution from LMT ONSRUD, a leader in cutting-edge solutions for aluminum extrusions. The success stories of LMT ONSRUD highlight the effectiveness of their tools and the significant benefits they provide to customers.

A Tale of Success

LMT ONSRUD's solutions for aluminum extrusions, specifically designed for Elumatec Machining Centers, have been crucial in numerous applications, demonstrating their superiority over competitors. Their cutting data is impressive, with tools like the 1-FL Spiral O Flute – 63-600 Series for aluminum extrusions operating at 18,000 RPM and 108 IPM, showcasing their efficiency and precision.

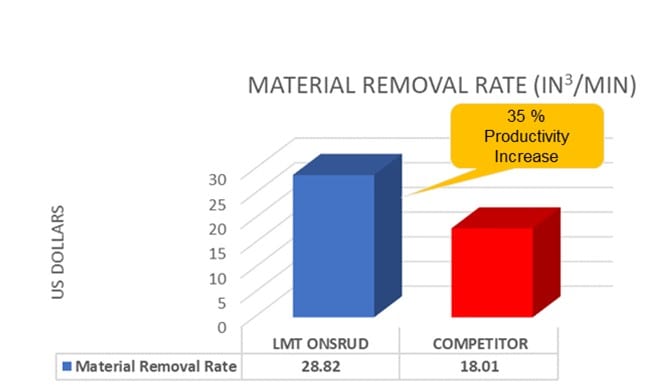

Compared to competitors, LMT ONSRUD's cutting tools not only provide better cutting data but also offer significant customer benefits. For example, their tools achieve a feed rate of 108 IPM, a marked improvement over the competitor's 71.80 IPM.

Figure 1 Elumatec Machining Center & Aluminum Extrusion Part

Figure 2 # 63-600 Series for Aluminum Extrusions from LMT Onsrud

Results

Customer Benefits & Savings:

- Increased productivity by 35%

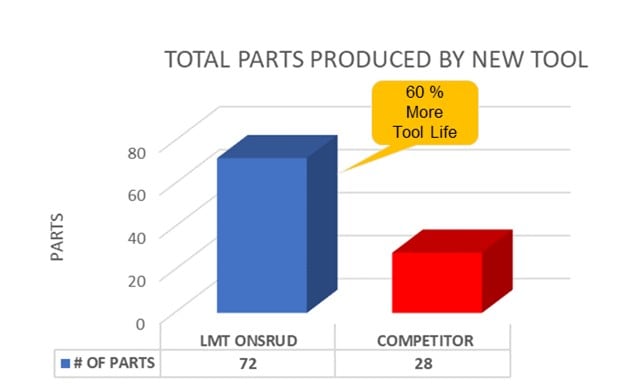

- Increased Tool life by 60%

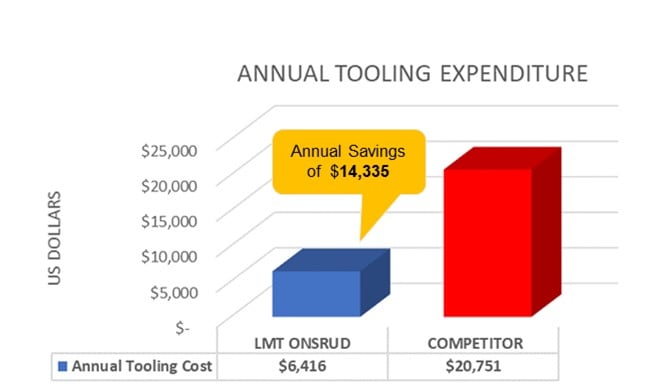

- Customer realized an annual savings of $14,335